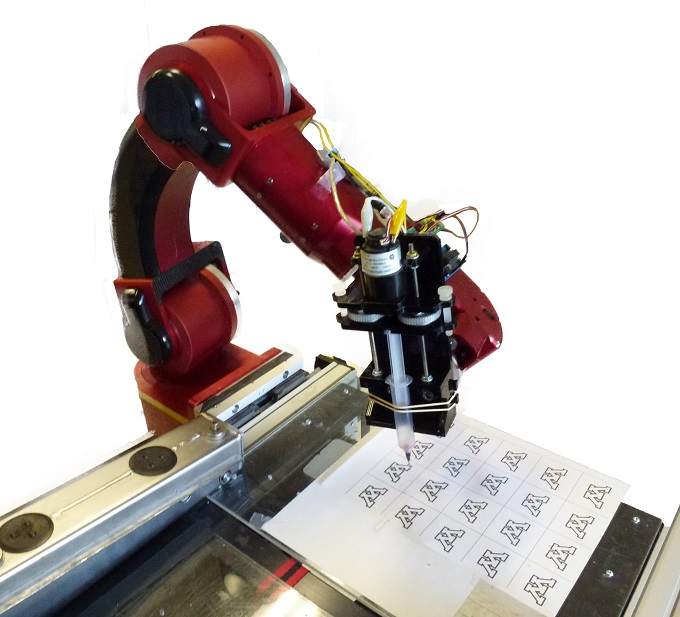

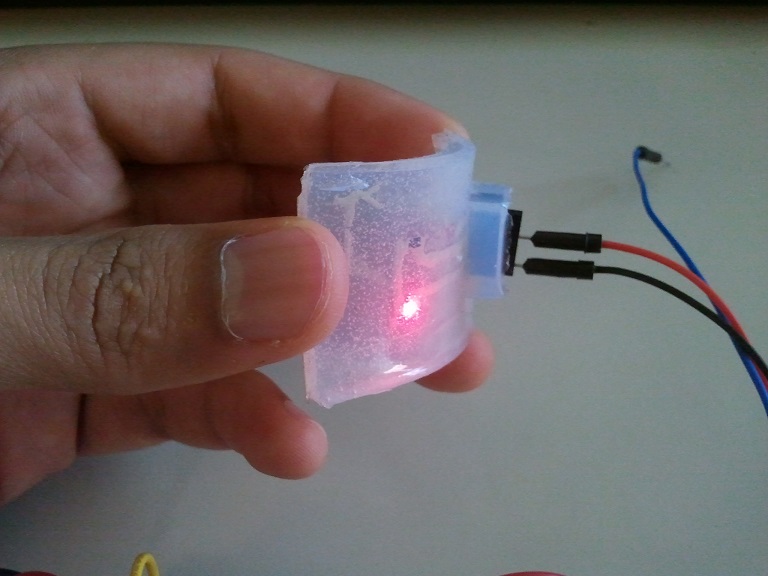

This work documents the development and testing of stretchable and flexible embedded circuits using additive manufacturing method. With the widespread popularity of desktop 3D printers the power of low-cost 3D printing can be harnessed to print electronics on stretchable and flexible bio-compatible skins with integrated circuitry, which can conform to irregularly shaped mounting surfaces. A multi-material freeform fabrication process with quick tool change provides the potential to print complete functional devices in a single manufacturing process, integrating the printing of both the structural and electronic blocks of the device. In this work, a custom-developed syringe-based controlled extrusion process using conductive silicone was developed for printing integrated circuits. The characteristics of the conductive silicone under stretching were studied. A proof-of-concept flexible bio-compatible skin device with an embedded voltage divider circuit was printed and the behavior of the device was studied under various working conditions. The researcher for this project was Sachin Bijadi.